“Some of the top things I have learned so far is to ask questions and to be curious. Usually these questions lead to more questions and eventually we start asking the right questions to the right people and answers start to emerge. Through this experience, I have learned that there is not a linear path when it comes to forming a business and I have to surround myself with the right people who can fill in the gaps of my knowledge.”

About the FoundHER(s)

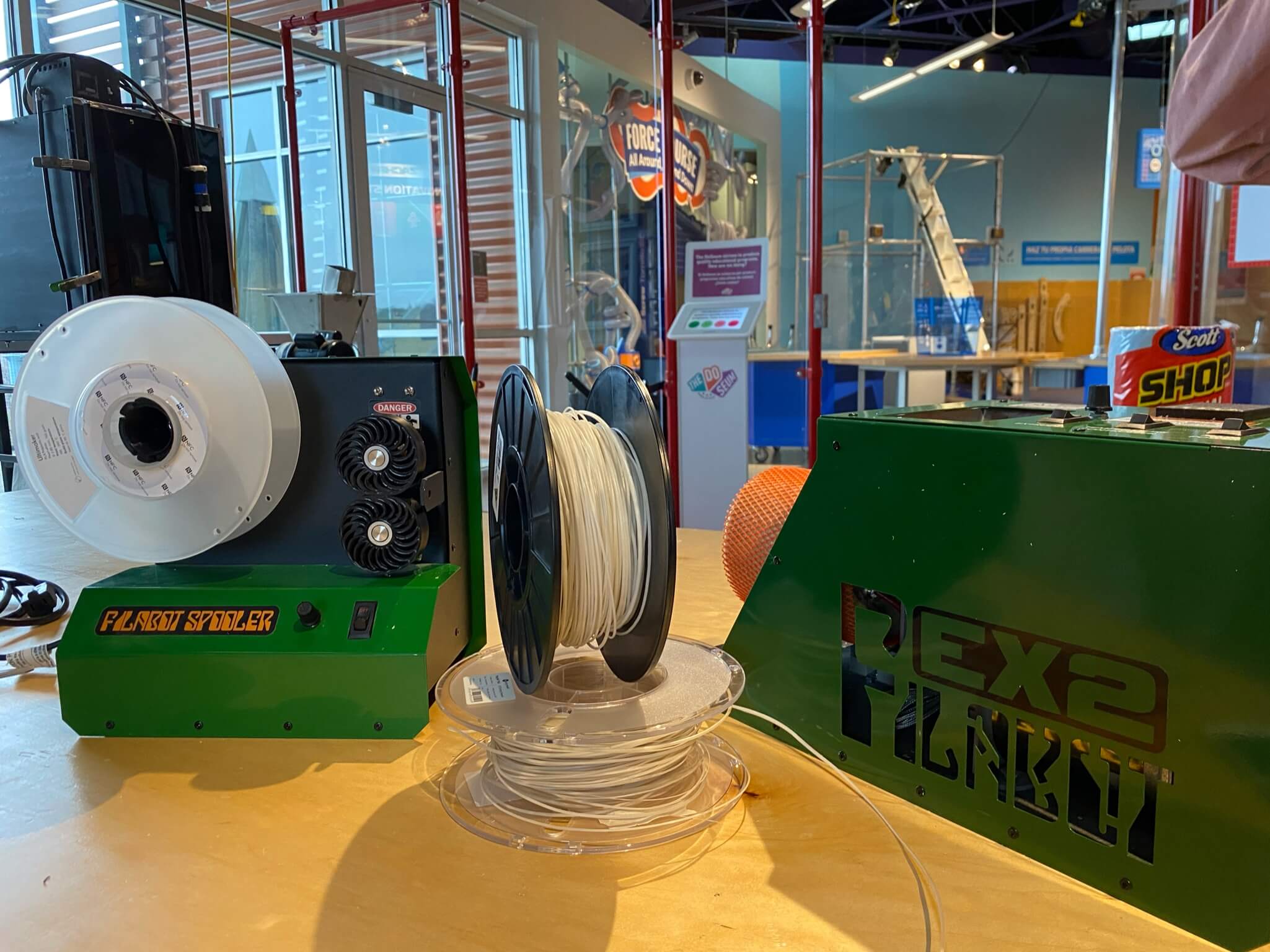

In high school, I worked for my family business, MAGI Foods, an oatmeal manufacturing company, and during this time I noticed how much of a hassle it was to dispose of the super sacks that carried the oats. It was costly to dispose of the plastic since it required baling and these sacks took up a lot of space on the manufacturing floor. I brought this problem to my business incubator class where we were working on creating a startup to pitch at the end of the year. As my team was brainstorming how we could utilize this plastic, we found out how much waste these super sacks produce yearly. For context, on a monthly basis, the typical manufacturer generates 1,000 to 2,000 super sacks, amounting to approximately 2,400 pounds of waste. This equates to an annual waste production of 28,800 pounds for a single manufacturer. We knew we wanted to find an outlet for this waste, but were torn on what that outlet should be. During one of our meetings, my teammate was showing us her new 3D printer pen, and she also noticed that the super sacks are made of polypropylene plastic, a plastic which is compatible with her 3D printer pen. The idea for FYDER was born.

About the Company

FYDER takes a byproduct of local manufacturing waste, the super sack, and extends its life by converting it into recycled polypropylene 3D printer filament. Super sacks are plastic woven bulk bags commonly used in manufacturing and end up in the landfills. Why is this a problem? On a monthly basis, the typical manufacturer generates 1,000 to 2,000 super sacks, amounting to approximately 2,400 pounds of waste. This equates to an annual waste production of 28,800 pounds for a single manufacturer. At FYDER we see an opportunity to divert this waste stream to produce recycled 3D printer filament for inventors and scholars alike to create consciously.

FYDER LLC

Website

Industry

Mission

At FYDER we believe technological innovation and environmental consciousness should go hand in hand. We aim to divert a plastic waste stream and produce fine filament spun sustainably for all to create

Year Founded

Nominate Today!

Know someone who would be a good fit for our FoundHER Program?

Nominations are open to anyone who is a part of the UT Austin ecosystem!